2.1 What is the purpose of this chapter? This chapter:

A. Gives our employees a logical and organized process for all phases of major construction projects built on Service lands that require engineering services.

B. Establishes common project management language that we can use consistently to improve understanding among Service architects and engineers, their clients, and stakeholders.

2.2 What is the scope of this chapter? This policy applies to all major construction projects built on Service lands that require engineering services.Construction projects include new construction, rehabilitation, and demolition projects.

2.3 What are the authorities for this chapter?

A. The Brooks Act: Federal Government Selection of Architects and Engineers, (P.L. 92-582).

B. Executive Order (E.O.) 12699, Seismic Safety of Federal and Federally Assisted or Regulated New Building Construction.

C. Federal Property and Administrative Services Act of 1949 (40 U.S.C. 471 et. seq.), as amended.

D. Public Contracts and Property Management, Government Furnished Quarters (41 CFR 114‑ 51) and Office of Management and Budget (OMB) Circular A-45, Rental and Construction of Government Quarters.

E. Public Buildings Amendments Act of 1988 (P.L. 100‑678).

F. Highways, Highway Bridge Replacement and Rehabilitation Program and National Bridge Inspection Program (23 U.S.C. 144 and 151) and Federal Highway Administration; Bridges, Structures, and Hydraulics (23 CFR 650).

G. E.O. 13423, Strengthening Federal Environmental, Energy, and Transportation Management.

H. National Dam Inspection Act (P.L. 92-367).

I. OMB Circular No. A-131, Value Engineering.

J. Architectural Barriers Act of 1968, as amended (42 U.S.C. 4151 – 4157).

K. Section 502 of the Rehabilitation Act of 1973, Architectural and Transportation Barriers Compliance Board (29 U.S.C 792).

L. Americans with Disabilities Act (P.L. 101-336).

M. Accessibility Guidelines for Buildings and Facilities issued under the Americans with Disabilities Act and the Architectural Barriers Act (36 CFR 1191).

N. Energy Policy Act of 2005 (P.L.109-58).

O. National Fire Protection Association 101, Life-Safety Codes.

2.4 What terms do you need to know to understand this chapter?

A. Consultant. A consultant may be a private company, an agency, or an organization. We access consultants through architectural or engineering services contracts, authorized partnerships, cooperative agreements, and memorandums of understanding to obtain various engineering services. In addition to private companies, some of the consultants we commonly use for construction include:

(1) The U.S. Army Corps of Engineers,

(2) The Bureau of Reclamation,

(3) The Federal Highway Administration,

(4) State conservation agencies, and

(5) Other non-profit organizations such as Ducks Unlimited.

B. Engineering Services. Engineering services include, but are not limited to: Qualified Engineering Reviews and Approvals, feasibility studies, surveys, engineering assessments, technical assistance, cost estimates, design and constructability reviews, peer reviews, value engineering studies (see 360 FW 3), architectural and engineering design, project management, construction management (see 360 FW 4), and environmental compliance services.

C. Project Management Plan (PMP). A PMP is a project management tool we use to improve our management of large, complex construction projects. It includes information on project scope, budget, schedule, roles, and responsibilities. It can be as short as a few pages or considerably longer depending on project size and complexity. The Project Manager (PM) prepares the PMP and gets appropriate approval before beginning the planning phase of a project. The PM updates the PMP periodically throughout the planning, design, and construction process (also see 360 FW 1.11).

D. Site-Adaptable Facility Designs and Standardized Floor Plans. Site-adaptable designs and standardized floor plans for facilities include the best examples of frequently constructed facilities (also see section 2.9). We keep these designs in a portfolio. We strongly encourage Project Leaders and PMs to use these designs wherever feasible. The designs include:

(1) Residences,

(2) Offices,

(3) Maintenance buildings,

(4) Storage buildings,

(5) Comfort stations, and

(6) Standardized floor plans for Visitor Centers and Administration Facilities.

E. Value Engineering (VE). Value Engineering is an organized review of the proposed design for a construction project to identify changes to a project’s design that would complete the project at a minimum life cycle cost of ownership and still meet project performance, reliability, quality, and maintenance requirements (also see 360 FW 3).

2.5 Who is responsible for project management for construction projects? We describe the responsibilities for our employees for all construction and engineering management activities (including project management) in 360 FW 1.5.

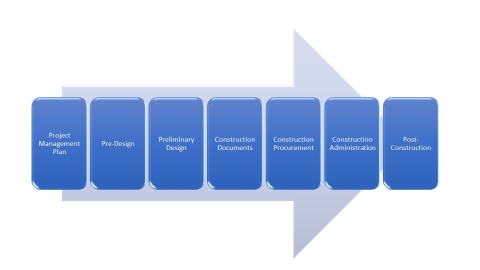

2.6 What are the major phases of a construction project? There are seven major phases of construction, each of which we describe in sections 2.6A through G below. Although the process is a structured series of activities from initial funding to post-construction evaluation, it is not a rigid order that all projects must follow precisely. You may modify project planning and engineering design milestones depending on the size and complexity of the project. (Also see Building the Future for Fish and Wildlife, 2001, for more detailed information on the process. Contact the Division of Engineering for a copy of the document.)

Summary of Major Phases of Construction:

A. Project Management Plan Phase. The Project Manager should develop a Project Management Plan (PMP) as the first phase of a project and update it periodically throughout the project as circumstances change. The PMP may be the most important document we develop during the course of a project.

(1) Content of the PMP. The PMP communicates essential project information to everyone involved in the project. The PMP includes:

(a) A clear and concise statement describing the project and why it is being done;

(b) The roles and responsibilities of all members of the project team;

(c) The schedule for key project phases; and

(d) The project budget.

(2) Funding Threshold. We must prepare and routinely update a PMP for all construction projects with a construction value greater than the deferred maintenance project threshold ($750,000 in 2006). We may choose to prepare a PMP for a project with a value less than the deferred maintenance project threshold if it is technically complex or has political implications.

(3) Review and Approval.

(a) For projects less than the deferred maintenance project threshold, the following officials must review and approve the PMP and updates:

(i) Project Leader,

(ii) Project Manager, and

(iii) Contracting Officer.

(b) For projects over the deferred maintenance threshold, in addition to the officials listed in the subsection above, the following officials must also review and approve the PMP:

(i) Assistant Regional Director for the affected Program, or the Regional Chief – National Wildlife Refuge System (NWRS), and

(ii) Regional Engineer.

B. Pre-Design Phase.

(1) The outcome of the Pre-Design phase are reports that give all stakeholders a comprehensive understanding of project functions and relationships and balance requirements with available or projected human and financial resources. Analysis during this phase should focus on the big picture—project objectives and scope.

(2) A Project Definition Report (PDR) is one of the key deliverables of the Pre-Design phase and should include:

(a) Project goals and objectives,

(b) Information needed to evaluate the feasibility of the project,

(c) Spatial requirements,

(d) Design and performance criteria,

(e) Site requirements,

(f) A preliminary project cost range,

(g) Initial project schedule,

(h) Identification of applicable codes and design standards (see section 2.10 for information about national building codes), and

(i) Description of issues that members of the community might have.

(3) Other activities during this phase may include:

(a) Analyses of alternative sites;

(b) Preparation of preliminary conceptual sketches;

(c) Identification of required permits and clearances; energy conservation features; and health, safety, and security requirements; and

(d) Development of quality assurance requirements.

C. Preliminary Design Phase. The third phase of a project is the Preliminary Design phase. We often refer to this as Title I – a term adapted from the U.S. Army Corps of Engineers, Civil Works Construction Management Regulations. This phase includes schematic design and design development.

(1) Goals. The goals of this phase are to:

(a) Develop a clearly defined and feasible conceptual design;

(b) Achieve client understanding and acceptance of the concept. The client is typically the refuge or hatchery Project Leader;

(c) Verification of compliance with project requirements, program, and budget;

(d) Description of all the important areas of the project so that all that remains is the design production and construction documentation.

(2) Activities. Activities during preliminary design may include:

(a) Conducting topographic and field surveys;

(b) Obtaining subsurface and soils data;

(c) Conducting site inspections and surveys for environmental contaminants (see 341 FW 3);

(d) Initiating permit applications and clearances;

(e) Preparing environmental documents;

(f) Coordinating with Service safety and health managers;

(g) Conducting technical engineering analyses and investigations of hydrologic/hydraulic, geotechnical (stability, seepage, etc.), and structural conditions of facilities;

(h) Drafting specifications;

(i) Preparing preliminary cost estimates and project schedules;

(j) Conducting energy evaluations of facilities, as appropriate (see 373 FW 2); and

(k) Conducting value engineering reviews (see 360 FW 3).

D. Construction Documents Phase. The purpose of the Construction Documents phase, or Title II, is to develop drawings and technical specifications that fully describe the work. A well-prepared set of drawings and specifications will give the construction contractor sufficient information to build the project and will reduce the chance of construction disputes and claims. The final construction documents usually include:

(1) Appropriately signed contract drawings and specifications in ready-to-advertise condition. Project documents should clearly explain the nature of work, site conditions, constraints, materials, and standards of performance. Specifications should require competitive products that meet or exceed the advertised requirements except for sole-source items approved by the Contracting Officer. Technical specifications must be consistent with Construction Specifications Institute (CSI) format. We may adjust the CSI version used to meet local construction and bid conditions.

(2) Final construction cost estimate for bidding purposes;

(3) Completed environmental permits and environmental documents prepared to comply with the National Environmental Policy Act (NEPA). See 550 FW 3 for more information on the documents that NEPA requires; and

(4) Bidding schedule/Schedule of Values (see 360 FW 1).

E. Construction Procurement Phase. The purpose of this phase is to hire a qualified construction company to build the project. (See section 2.12 for more information about procurement.) There are many different ways of procuring construction services, including Low-Bid, negotiated procurement, HUBZone, and Design-Build.

(1) Low-Bid Procurement. For the Low-Bid process, we procure services based on the lowest bid received from construction contractors responding to a request for bids. Before awarding contracts, we verify that the contractors are technically qualified to provide the services.

(2) Negotiated Procurement. For the negotiated procurement process, we select the construction contractor only after negotiating price with one or more qualified contractors. We typically use this process for procurements such as Small Business Administration set-asides (8A) or HUBZone procurements (see subsection below).

(a) A form of negotiated procurement includes the Best Value Procurement process. For best value, we evaluate the construction contractors based on past performance, bid price, technical qualifications, experience, and price based on criteria outlined in the solicitation.

(b) Using the best value selection process, the contractor we select may not be at the lowest price, but represents the best value to the Government.

(3) HUBZone Empowerment Contracting. Congress established the HUBZone Empowerment Contracting program to encourage economic development in historically underutilized business zones. The program promotes Federal contracting assistance for qualified small businesses such as construction contractors. The program’s goal is to increase employment opportunities and investment in economically distressed areas.

(4) Design-Build. In 1997 the Federal Acquisition Regulation (FAR) was modified to allow Design-Build as an alternate project delivery system. Design-Build firms are responsible for the design process and documents, as well as all construction.

(a) Advantages:

(i) Because the designer-builder is one entity, usually it completes the project in a shorter period of time than if we hired more than one contractor.

(ii) Often the project will cost less.

(iii) Because they are together by choice and form one team, the designer, builder, and any subcontractors should work well together.

(iv) Errors and omissions in the construction documents are the Design-Build team’s responsibility. The Service does not assume that risk.

(v) A single source of responsibility for design and construction usually results in fewer change orders during construction.

(b) Disadvantages:

(i) We give up some control of the design because we do not have as much architect/engineer representation during design.

(ii) It puts tremendous pressure on us to know and clearly define criteria and quality for the project at the start. Failure to do so can result in a disappointing outcome or in a facility that does not meet our needs or expectations.

F. Construction Administration Phase. This phase is when the actual construction takes place. Even the best-conceived and designed project can falter if we do not properly administer the work. The goals of the Construction Administration phase are to:

(1) Ensure the project is constructed in accordance with the plans and specifications;

(2) Meet all functional and contract requirements relative to quality;

(3) Complete the project within the anticipated cost;

(4) Complete the project on schedule; and

(5) Ensure client satisfaction throughout and at the end of construction.

G. Post-Construction Phase. This phase begins after the construction contract is complete.

(1) The objective of post-construction is to ensure that the client is satisfied with the project.

(2) Post-construction activities may include:

(a) Monitoring initial project performance,

(b) Monitoring client satisfaction,

(c) Debugging, which includes addressing any project performance issues that arise after construction is complete,

(d) Commissioning and post-construction training.

(3) Post-construction activities must include warranty administration and a final inspection.

2.7 Are there any exceptions to using the process described above for the planning, design, and construction of a construction project that requires engineering services? There are three exceptions to following the sequence described in section 2.6:

A. We may construct some projects using standard engineering designs, designs completed for similar projects, or "off-the-shelf" prefabricated structures. Use of standard plans and engineering designs or site-adaptable facility designs reduces or eliminates many of the phases we describe above (see section 2.9 for more information on site-adaptable facility designs).

B. Technically straightforward projects that require minimal engineering involvement may also eliminate the need to follow some of the phases in section 2.6. Examples of such projects are storm debris removal not involving regulated or hazardous materials and re-surfacing an existing roadway.

C. In response to an emergency situation, we may plan, design, and construct projects under accelerated schedules and processes.

2.8 What is the Service’s policy for development of sustainable designs for facilities? In addition to the requirements of the Energy Policy Act of 2005 (Public Law 109-58), our staff and consultants must adhere to the guiding principles included in E.O. 13423, Strengthening Federal Environmental, Energy, and Transportation Management, and the Department of the Interior Federal Leadership in High Performance and Sustainable Buildings Implementation Plan, January 2007.

A. These guiding principles cover:

(1) Integrated design;

(2) Energy performance;

(3) Water conservation; and

(4) Indoor environmental quality and construction materials.

B. Goals of the Department’s Implementation Plan are to:

(1) Reduce the total ownership cost of facilities;

(2) Improve energy efficiency and water conservation;

(3) Provide safe, healthy, and productive built environments; and

(4) Promote sustainable environmental stewardship.

C. Typical sustainable design features include, but are not limited to:

(1) Recycled content of construction materials;

(2) Renewable energy technologies, such as photovoltaics, wind, ground source heat pumps, passive solar heating, and biomass;

(3) Energy efficient technologies such as motion detection systems, lighting retrofits, high efficiency HVAC systems, and energy management control systems;

(4) Water saving technologies;

(5) Individual building utility meters;

(6) Upgraded building insulation, windows, and doors; and

(7) Procuring Energy Star or Federal Energy Management Program-recommended products.

2.9 What is the Service’s policy for using Site-Adaptable Facility Designs and standard floor plans?

A. We strongly encourage the use of site-adaptable facility designs to minimize planning and design costs. Site adaptable designs are in, "Site-Adaptable Facility Designs, A Planning Guide For New Projects, Project Examples for Housing, Office Buildings, Maintenance Buildings, Storage Buildings, and Comfort Stations (2002)." Managers also may use proven Regional designs when planning similar facility types. The Site-Adaptable Facility Designs Guide is available on the Division of Engineering’s intranet page or by contacting the DEN. The DEN can also give you the guide in hard copy or on compact disc.

B. There is also a cost estimating and planning model to use for constructing new visitor and administrative centers. Managers must use this tool when developing concept level cost estimates for future visitor and administrative facilities. Managers may also use it to determine component sizes and values when Congress adds funding to the Service’s budget with little or no specificity on architectural component cost.

C. The National Wildlife Refuge System staff developed standard visitor center floor plans to lower preliminary planning costs and to give centers a consistent look and feel. These floor plans are available by contacting the Headquarters, National Wildlife Refuge System Staff.

2.10 What are the requirements to follow national building codes on Federal construction projects?

A. We must follow the following codes whenever we build or alter a facility:

(1) Nationally recognized model building codes, such as the Uniform Building Code (UBC) or International Building Code (IBC);

(2) Other applicable nationally recognized codes include, but are not limited to, electric codes, mechanical codes, fire and life safety codes, and plumbing codes; and

(3) The National Fire Protection Association (NFPA) 101, Life Safety Code as the minimum criteria for life-safety features.

B. The Regional Engineer determines which codes apply.

C. If there are conflicts between the national, State, or local codes, we recommend using the more stringent code. If the more stringent code is not followed, the Authority Having Jurisdiction (see 360 FW 1.4A) must justify all deviations in writing.

2.11 What is the process for making changes during the Pre-Design or Preliminary Design phase? Once we begin engineering design, the Regional Director must approve any substantive changes to a project. The Regional Director will only consider changes if:

A. The purpose of the facility changes,

B. We identify technological advances that we can use to improve effectiveness or efficiency of operations,

C. The changes will result in cost savings (e.g., they are recommended in a value engineering review), or

D. The changes are necessary to ensure we comply with applicable Federal and State laws and regulations (e.g., the selected alternative in the environmental document or the Section 106 consultation process of the National Historic Preservation Act).

2.12 What information does the Contracting Officer need from Engineering Services to procure construction contractors? The Regional Engineer or the Chief, DEN, or their designees, must coordinate with the appropriate CO to ensure that projects proceed efficiently. The Regional Engineer or Chief, DEN must provide:

A. Synopsis for FedBizOpps. Before the CO issues a solicitation, the CO must post a synopsis on FedBizOpps.gov for any project we estimate will cost more than $25,000 (or $10,000 if only one offer is anticipated). FedBizOpps.gov is the Government Website for all procurement opportunities over $25,000. The Regional Engineer or the Chief, DEN, or their designee should submit a summary of the project to the CO as soon as possible in the process to keep to the project schedule.

B. Davis-Bacon Wage Rate Requests. The Regional Engineer, or the Chief, DEN, or their designee, should send a wage rate request to the CO at the start of the Pre-Design phase to expedite preparation of the solicitation.

C. Authorizing Large Projects. Prior to issuing a solicitation for a contract, the CO should determine and comply with Department of the Interior pre-solicitation clearance requirements. If required, the Regional Engineer or the Chief, DEN, must give the CO a description of the work to be performed at least 2 weeks before sending the CO drawings and specifications. The CO needs this information in advance to obtain the necessary approval and to proceed with the acquisition process.

D. Submitting the Bid Package. When engineering design work is complete, the Regional Engineer or Chief, DEN must send the CO a bid package that includes:

(1) The technical specifications,

(2) Construction contract drawings,

(3) Bidding schedule/Schedule of values,

(4) Independent Government cost estimate,

(5) Contract completion period,

(6) Potential bidders list,

(7) Required permits and clearances,

(8) Accounting data, and

(9) Cost rationale for any suggested liquidated damages rates.