TABLE OF CONTENTS

| Topics | Sections |

|---|---|

| OVERVIEW | 5.1 What is the purpose of this chapter? 5.2 What is the scope of this chapter? 5.3 What is the overall policy for safety and occupational health inspections at the Service? 5.4 What are the authorities for this chapter? 5.5 What terms do you need to know to understand this chapter? |

| RESPONSIBILITIES | 5.6 What are the primary responsibilities associated with the inspection program? |

| INSPECTION REQUIREMENTS - ANNUAL AND PERIODIC | 5.7 What are the requirements for conducting annual safety and occupational health self-inspections? 5.8 What should a Project Leader expect from a periodic Joint Administrative Operations inspection of the facility's safety and occupational health program? |

OVERVIEW

5.1 What is the purpose of this chapter? This chapter establishes procedures and responsibilities for conducting annual self-inspections and formal periodic safety and occupational health inspections at U.S. Fish and Wildlife Service (Service) facilities and correcting any deficiencies.

5.2 What is the scope of this chapter?

A. This chapter applies to all Service facilities.

B. Project Leaders/Supervisors/Facility Managers have many responsibilities for this program. For simplicity, throughout this chapter we refer to them collectively as Project Leaders.

5.3 What is the overall policy for safety and occupational health inspections at the Service? The Service requires that all facilities perform an annual safety and occupational health self-inspection. The Joint Administrative Operations (JAO) Safety Operations office also conducts periodic, comprehensive inspections of all facilities’ safety and occupational health programs.

5.4 What are the authorities for this chapter?

A. Basic Program Elements for Federal Employee Occupational Safety and Health Programs and Related Matters (29 CFR 1960).

B. Executive Order 12196, Occupational Safety and Health Programs for Federal Employees.

C. Executive Order 12564, Drug-Free Federal Workplace.

D. Occupational Safety and Health Act, Federal Agency Safety Programs and Responsibilities (Public Law 91-596, Sec.19).

E. 485 Department of the Interior (Department) Manual (DM) 6, Inspections and Abatement.

5.5 What terms do you need to know to understand this chapter?

A. Collateral Duty Safety Officer (CDSO). An individual designated either onsite or at another site to advise and assist a Project Leader to achieve their responsibility to implement the station’s safety and occupational health program.

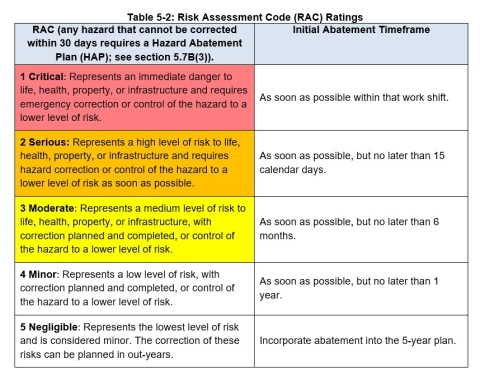

B. Hazard Abatement Plan (HAP). A management plan for addressing any identified hazards that cannot be corrected in order of priority within 30 days. If hazards cannot be or will not be corrected within 30 days of their identification, the Project Leader must develop a short but concise HAP using the Risk Assessment Code (RAC) timeframes we describe in Table 5-2 (also see Exhibit 1). The HAP lists the steps taken to temporarily alleviate the hazard to employees and those steps they will take to permanently correct it. RAC timeframes and the 30-day abatement requirement run concurrently.

C. Risk Assessment Code (RAC). A measurement of the likelihood (probability) and the consequences (severity) of a particular hazard to cause harm to employees. All hazards identified must have a RAC rating of 1 to 5. See section 5.7B for details.

D. Self-inspection. An annual, station-level occupational safety and health evaluation that is either conducted by the station CDSO or a supervisor, or both. Self-inspections must be completed by August 31 of every year.

RESPONSIBILITIES

5.6 What are the primary responsibilities associated with the inspection program? SeeTable 5-1.

Table 5-1: Responsibilities for Safety and Occupational Health Inspections

| These employees... | Are responsible for… | |

|---|---|---|

| A. The Director | Approving or declining to approve Servicewide policy for safety and occupational health inspections. | |

| B. The Assistant Director – Management and Administration (serving as our Designated Agency Safety and Health Official) | (1) Overseeing the establishment and management of overall policy and guidance for the efficient and effective safety and occupational health inspection program; and (2) Providing sufficient support and resources to the Chief, JAO Safety Operations, to ensure that the Chief can accomplish program goals. | |

| C. Regional Directors or appropriate Directorate members for inspections in Headquarters | (1) Implementing the requirements in this chapter, and (2) Ensuring that Project Leaders within the Regions/programs take appropriate action to correct safety and occupational health deficiencies within the timeframes in Table 5-2. | |

| D. The Chief, Safety Operations (under the JAO organization) | (1) Revising and updating this chapter, as necessary; (2) Interpreting the requirements in this chapter and resolving issues and questions about this policy throughout the Service; (3) Providing the necessary tools (i.e., checklists, forms, instructions, and inspection completion deadlines) for stations to accomplish and document an annual self-inspection of their facilities and operations; and (4) Ensuring that a schedule is established and implemented by responsible Safety Managers/Specialists to perform periodic, comprehensive safety program inspections at field stations and other facilities. | |

| E. Responsible JAO Safety Managers/ Specialists | (1) Advising Project Leaders, CDSOs, and employees on the implementation of the safety and occupational health inspection program; (3) Coordinating with stations on scheduling and conducting upcoming periodic safety inspections; (4) Working with Regional Business Advisors and their staff on issues requiring coordination with Regional programs and JAO Safety Operations; (5) Following up with Project Leaders about resolutions to safety hazards and any HAPs every 90 days until the hazards are resolved; (6) Providing technical assistance as requested to Project Leaders and CDSOs to identify and assess safety and occupational health hazards and appropriate corrective actions; and (7) Sending copies of any Occupational Safety and Health Administration (OSHA) written reports or Notices of Violation issued to Service facilities within their areas of responsibility to the Chief, JAO Safety Operations as soon as they are received. | |

| F. Facility Management Coordinators | Working with Project Leaders, as needed, to address un-resolved, long-term safety findings that are currently under a HAP, which may include entering them into the 5-year maintenance plan for the facility. | |

| G. Project Leaders (collective term that refers to Project Leaders, Supervisors, and Facility Managers) | (1) Continually monitoring operations, facilities, and equipment to ensure employees are safe from recognized hazards and to prevent injuries, occupational illness, and accidents that cause property damage; (2) Ensuring a qualified individual conducts an annual safety and health inspection and documents the findings in the online safety system; (3) Reviewing and approving their annual self-inspection reports in the online safety system; (4) Downloading, as needed, the self and formal safety inspection results and any corrective actions and HAPs from the online safety system and maintaining them for a minimum of 5 years; (5) Correcting safety and occupational health hazards identified in the annual self and periodic safety inspections as quickly as possible and within the timeframes in Table 5-2, and documenting those corrective actions within the online safety system, Kip Prahl & Associates (KPA EHS) Flex. (6) Developing a HAP through the online safety system for hazards that cannot be corrected within 30 days (see section 5.7B(3)); (7) Coordinating with their Facility Management Coordinator to ensure safety items requiring additional money and time are addressed in the 5-year Deferred Maintenance and Capital Improvement Plan; (8) Ensuring residents of Government quarters are notified of upcoming safety inspections of residences, and notifying the evaluator about any specific issues raised by the residents, such as timing, children, pets, etc.; and (9) Sending copies of OSHA reports or Notices of Violation issued to facilities for which they are responsible to the Chief, JAO Safety Operations as soon as they’re received. | |

| H. Collateral Duty Safety Officers (CDSO) | (1) Complying with Service policy in 240 FW 2, Collateral Duty Safety Officer; and (2) When requested by the Project Leader, conducting and documenting an annual safety and occupational health inspection. | |

| I. Employees | (1) Reporting safety and occupational health hazards or concerns to their immediate supervisors, and (2) Cooperating during inspections and with implementing corrective actions. | |

INSPECTION REQUIREMENTS - ANNUAL AND PERIODIC

5.7 What are the requirements for conducting annual safety and occupational health self-inspections? OSHA requires annual completion of a documented safety and occupational health inspection at all of our facilities. We use annual facility self-inspections to comply with the requirement. These inspections may be completed any time prior to August 31st but must be completed by August 31st annually.

A. Inspector training/experience. Project Leaders must ensure that a qualified person conducts the annual self-inspection for the facilities and operation(s) for which they are responsible. If a facility has a CDSO, then the CDSO should either conduct or participate in the inspection process. In some offices (e.g., Regional offices, HQ, and the National Conservation Training Center), the CDSO’s responsibilities may cross program divisions, so those facilities’ station safety plans must describe who conducts and reviews annual inspections.

(1) Inspectors must have taken, at a minimum, the FWS CDSO course (SAF-SAF-CDSO), which includes training on hazard recognition and safety and occupational health inspection procedures.

(2) Inspectors must also have the knowledge and skills needed to recommend corrective actions (see 240 FW 2). Contact your responsible JAO Safety Managers/Specialists for additional guidance.

B. Inspection results. All inspection findings/results/corrective actions must be entered into the Service’s online safety system, KPA EHS. Project Leaders must sign and date inspection reports to show that they have reviewed them. They must also maintain electronic copies of the reports at the office/field station and provide them to the Regional or HQ office, if requested.

(1) If an inspector finds a safety or occupational health hazard that could cause death or serious physical harm, the Project Leader must take immediate corrective or preventive action, and if necessary, stop the operation or evacuate the area.

(2) Inspectors must assign Risk Assessment Codes (RAC) to hazards they identify. The RAC is a measurement of the likelihood (probability) and the consequences (severity) of a particular hazard. See Table 5-2 below and Exhibit 1 for information on how to assign a RAC to a hazard. All hazards identified must have a RAC rating, which go from 1 to 5.

(a) The use of RACs helps management prioritize resources to abate the most critical hazards or deficiencies on a worst-first basis.

(b) The RAC is an expression of risk, combining the likelihood and consequences of a hazardous condition that would result in an accident, illness, or injury.

(3) The Project Leader must correct all identified hazards in order of priority within 30 days.

(a) If, after 30 days, there are any hazards with RACs of 1, 2 or 3 that cannot be or will not be corrected, the Project Leader must develop a short but concise HAP using the RAC timeframes in Table 5-2 and explained in Exhibit 1. (Project Leaders may choose to assign more stringent timeframes for abating hazards than those in Table 5-2.). The HAP must list the steps taken to temporarily alleviate the hazard to employees and those steps they will take to permanently correct it. RAC timeframes and the 30-day abatement requirement run concurrently.

(b) While hazards with RACs of 4 or 5 do not have a HAP requirement, resolution is still required within the timeframes in Table 5-2 and Exhibit 1.

(c) Project Leaders should contact the responsible JAO Safety Manager/Specialist for assistance with safety hazard resolutions, including use of the HAP, and ensure that updates are made in the online safety system, KPA EHS, every 90 days until the hazards in the HAP are resolved. The Project Leader also must initiate a request for additional resources when necessary to correct the hazard.

C. Ongoing monitoring and new facilities.

(1) The requirement for an annual safety self-inspection does not relieve the Project Leader of the responsibility to continually monitor performance and operations to ensure employees are safe on the job.

(2) Before facilities are occupied by Service employees or members of the public, a safety and health professional or other qualified person (e.g., engineer, architect, fire safety officer) must conduct a pre-occupancy inspection for safety and health issues as either a separate activity or as part of a final inspection. This requirement applies to newly built structures, to facilities newly obtained by the Service, and to major renovation projects. The inspector must document findings and report them to Regional or HQ management as well as to the JAO Safety Operations staff. Based on the inspection findings, the responsible inspector recommends occupancy of the space or identifies corrective actions needed to bring the space into a safe and healthful condition before it is occupied.

D. When others (i.e., from outside the facility) conduct a safety inspection.

(1) Safety and health officials from OSHA, the Department, and the Service have the right of entry without delay, at reasonable times, to any facility, construction site, or other Service workplace to perform an inspection. They also have the right to inspect any item or place within the workplace, and to question any manager, employee, or visitor. For non-emergency safety and health inspections of Government quarters, a minimum of 48 hours advance notice is required whenever possible.

(2) If OSHA personnel arrive to conduct an inspection, the Project Leader or other staff must immediately contact their responsible JAO Safety Manager/Specialist, who will notify the Chief, JAO Safety Operations. The Project Leader must send a copy of the OSHA written report they receive and a copy of the formal response to the report to the responsible JAO Safety Manager/Specialist. Any OSHA written report or Notice of Violation must be provided to the Chief, JAO Safety Operations. The Chief distributes these reports to the other Regions to keep them informed, as appropriate.

5.8 What should a Project Leader expect from a periodic JAO inspection of the facility's safety and occupational health program? The purpose of the formal inspection is to determine to what extent the Project Leader has implemented a safety and occupational health program that meets OSHA, Departmental, and Service requirements. Although JAO Safety Operations usually gives prior notice about the inspection, they don’t have to. Facilities may be asked to provide updated safety documents, such as written programs, for review prior to the inspection visit. If applicable, the Project Leader should notify any involved union representatives and allow them to attend the inspection if they would like to do so.

A. All facilities undergo a formal overall safety and occupational health inspection that JAO Safety Operations conducts. These inspections are scheduled with the stations directly and are conducted at least every 3 years. Those stations with higher risks or increased injury/illness rates may be inspected more frequently as determined by the JAO Safety Operations office.

B. The responsible JAO Safety Manager/Specialist initially meets with the Project Leader and the CDSO to go over the inspection process and determine if there are any particular safety issues of concern.

C. The inspection is detailed enough to determine safety and health program effectiveness. This may include a review of any combination of the following:

(1) OSHA written programs. OSHA requires that we develop station-specific written programs to comply with regulatory standards when tasks, associated hazards, and level of exposure warrant them. Examples of activities or circumstances requiring written programs include confined spaces, bloodborne pathogens, hazard communication, lock-out /tag-out, and respiratory protection;

(2) Training records;

(3) Accident reports;

(4) Annual inspection reports;

(5) HAPs (management action plans);

(6) Safety certification statements, if required in the Region or at HQ;

(7) Other safety and health program-related items; and

(8) Physical inspection of the facility.

D. At the end of the visit, JAO Safety Operations personnel must hold a closeout meeting to discuss their findings with the Project Leader and other appropriate staff. The responsible JAO Safety Manager/Specialist must send a written report documenting the findings and any recommended corrective actions to the Project Leader within 30 calendar days. The Project Leaders and other managers are responsible for correcting deficiencies as described in this policy.